Optimizing Fleet Component Replacement through Redefined Lifecycle Strategies in Global Logistics Enterprises

Main Article Content

Abstract

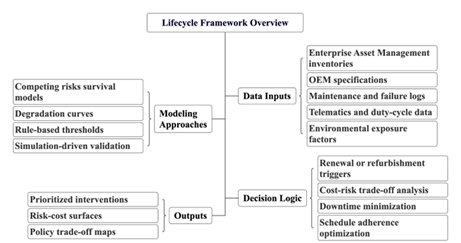

This paper presents an integrated, value-based framework for lifecycle planning in heterogeneous enterprise truck fleets. While failure models exist, forecasting remains unreliable under variable duty cycles, regulation, and environmental exposure. The gap is the absence of a unified scheme that links asset segmentation by business value to explicit risk-tolerance thresholds and mapped interdependencies. We assemble Enterprise Asset Management (EAM) inventories, original equipment specifications, maintenance and failure logs, telematics, and lead times; harmonize records; and model deterioration using competing risks survival, degradation curves, and rule-based triggers. Decision logic optimizes lifecycle cost and downtime under parts, workshop, and regulatory constraints, with audit trails and explanations. Validation uses simulation-driven testing with multi-agent routing and scheduling, scenario-based thresholding, and bootstrap sensitivity. Outcomes indicate prioritized interventions, qualitative reductions in unplanned failures and downtime, improved schedule adherence, and cost-risk surfaces that support policy trade-offs; agreement of labels and priority bands is assessed using Cohen's kappa. Sensitivity analyses probe segmentation thresholds, refurbishment-cost assumptions, and interdependency weights. The contribution is an operational framework that codifies risk thresholds into renewal or refurbishment triggers and aligns decisions with sustainability and total cost of ownership. Practitioners can apply the framework to implement auditable, locally calibrated renewal policies across regions.

Article Details

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.